New York City Sanitation Building

New York, NY

Project

New York City Sanitation Building Multi-Source, Multi-Use

New York City was planning a 400,000 square foot facility to house and maintain half its fleet of municipal waste vehicles and wanted to build a sustainable LEED certified building. In addition to needing water to wash trucks and irrigate landscaping, 108 workers will flush toilets and an estimated 2 million gallons of water will be needed annually for the cooling system. Engineers Greeley & Hansen asked Wahaso to help design and build a system to reduce municipal water use in the building.

Challenge

Nearly four million gallons of annual water usage was identified that could be replaced by non-potable water for uses like the cooling tower and toilet flushing. But no one water source for reuse could come close to meeting the total demand. So Wahaso evaluated multiple sources that could be combined and used together to meet the demand.

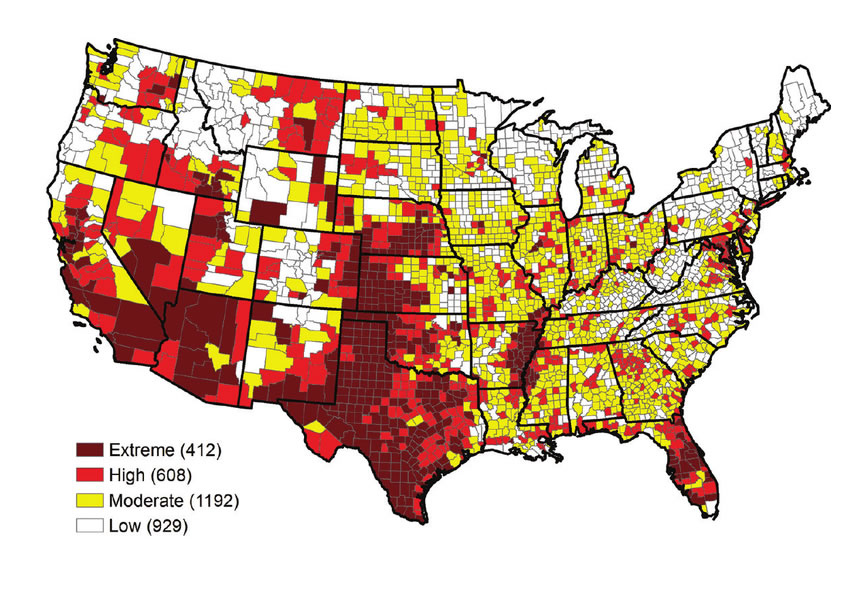

Water Supply Sustainability Index (2050)

Project Details

LOCATION

New York, NY

CLIENT

New York City Department of Sanitation

DESIGN & SPECIALTY

Plumbing Engineer, Civil Engineer, Commercial Contractors, Commercial Architect

BUILDING TYPE

Office

SYSTEM TYPE

Multi-Source, Multi-Use

COMMISSIONING DATE

September, 2013

Project Gallery

Solution

Water will be collected from the building’s roof and from cooling condensate, but the really big supply will be condensate harvested from the steam heat supplied by the city. There is no return loop for steam in the city, so all condensate normally goes to the sewer system.

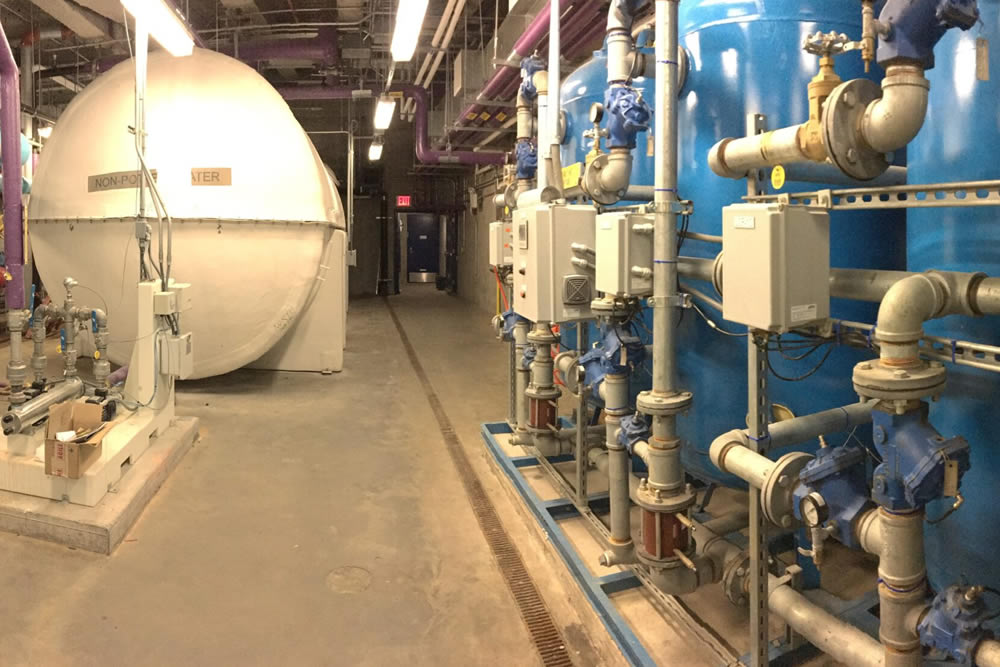

Wahaso designed a system using multimedia filtration and a combination of chlorine and U.V. for sanitation depending on how the water will be used. The only place for the 20,000 gallons of storage required was in the building’s basement, so a tank from Edwards Fiberglass was delivered during construction so the building could be built around the tank. Comprehensive 3-D modeling of all skids ensured that equipment would fit the prescribed spaces and that the final skid production would match the intended design.

Results

The building is still in construction and is expected to be commissioned in 2014. Harvested water will be used for cooling tower make-up (2 MM Gals), toilet flushing (1.3 MM Gals), truck washing (340K Gals) and green roof irrigation (200K Gals) – for a total of 3.8 million gallons of savings worth about $40K per year.