Greywater GreyFlo Series — By Wahaso

Greywater Harvesting Systems

Summary

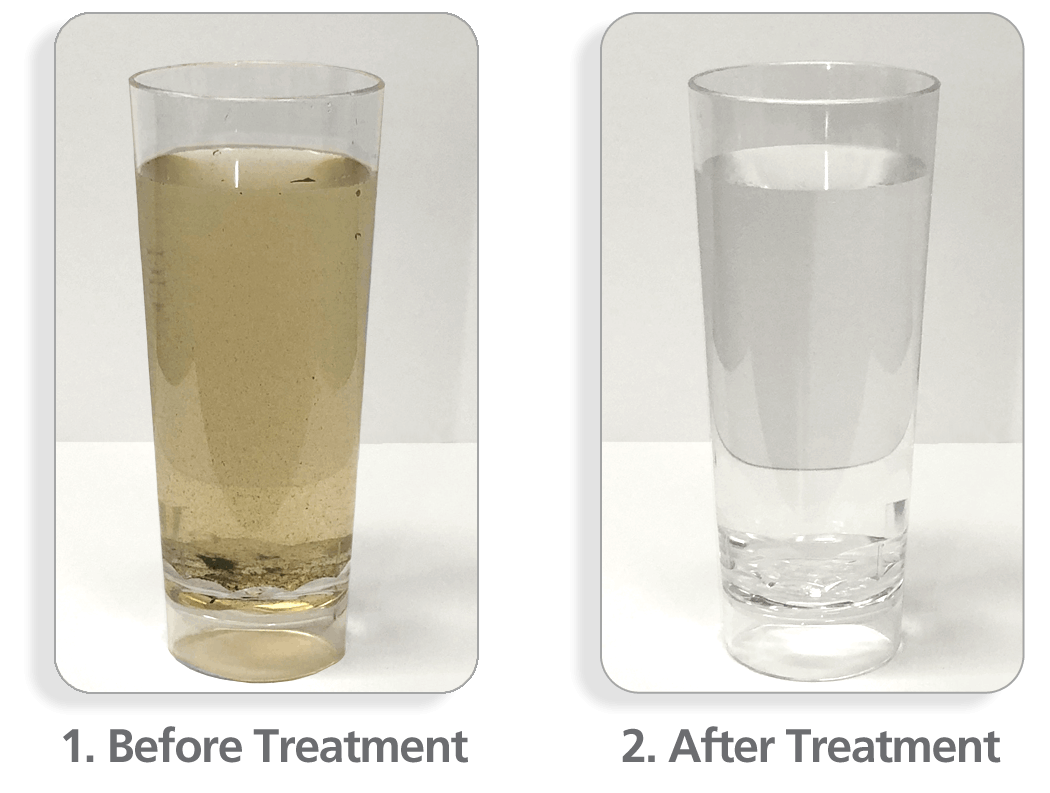

Greywater (also referred to as graywater, grey water, and gray water) is “gently used” water captured from showers, lavatory sinks, laundry, and light commercial processes. Learn more

Key Takeaways

- Explore Wahaso’s Packaged Greywater Systems

- It can often be an excellent source of water, saving thousands or even millions of gallons of water per year.

- Given the contaminants inherent in greywater, it is important that any grey water systems are designed properly.

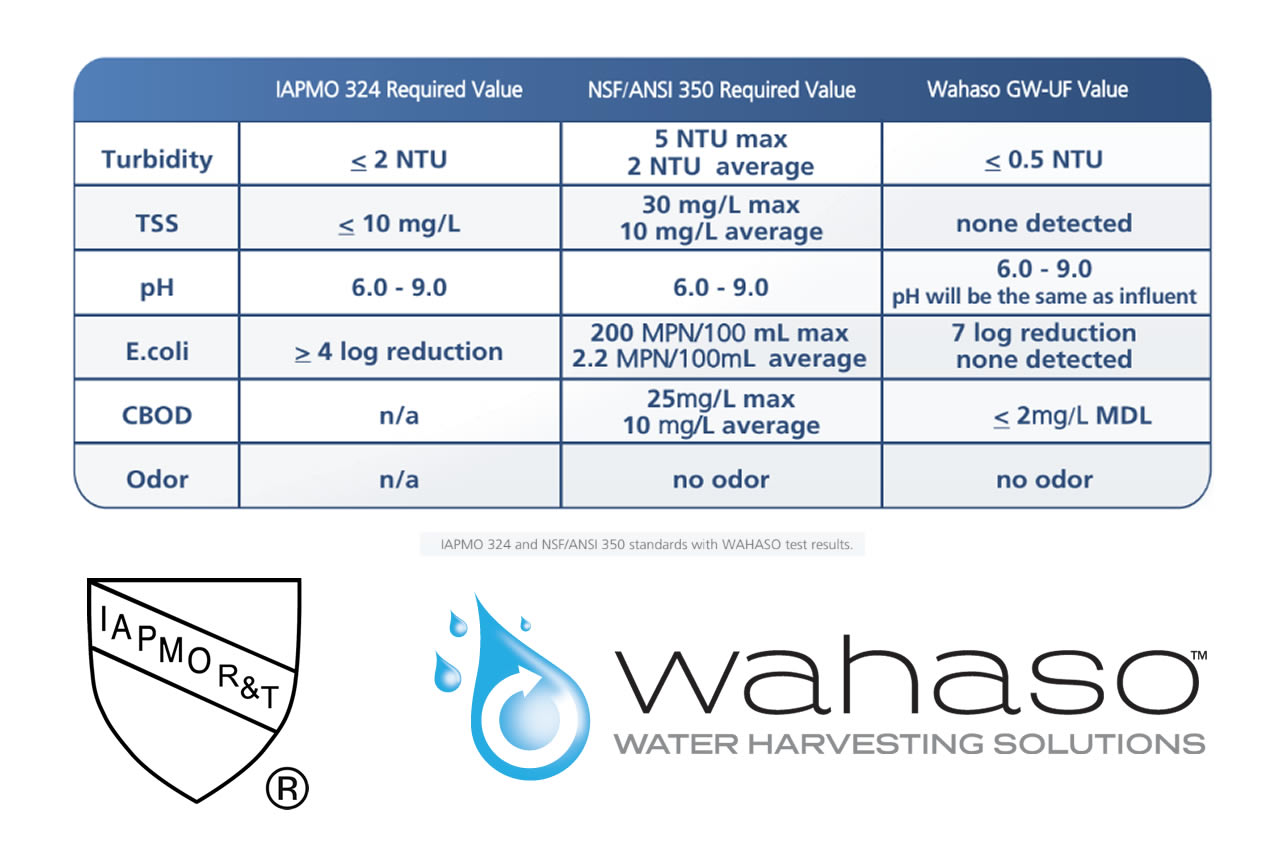

- Wahaso’s grey water recycling systems for commercial properties has been certified to meet both IAPMO 324 and NSF/ANSI 350 standards.

- The Wahaso greywater harvesting system has been tested and proven to provide a safe, treated supply of water that can be used for a variety of non-potable applications.

Wahaso — GreyFlo Series

Packaged Greywater Systems

Certified Greywater Systems. Proven Results.

Wahaso was among the first in the U.S. to deliver commercial greywater reuse systems—and we still lead the way. Certified to IAPMO IGC 324 and NSF/ANSI 350, our systems are built for performance, reliability, and code compliance. From design to commissioning, we make integration seamless for architects, developers, contactors and engineers.

Greywater System Product Features

→ Proven Payback + ROI

→ Trusted Nationwide

→ BAS Integration Ready

→ Low-Maintenance Design

→ Pre-Wired + Pre-Plumbed

→ Certified for Compliance

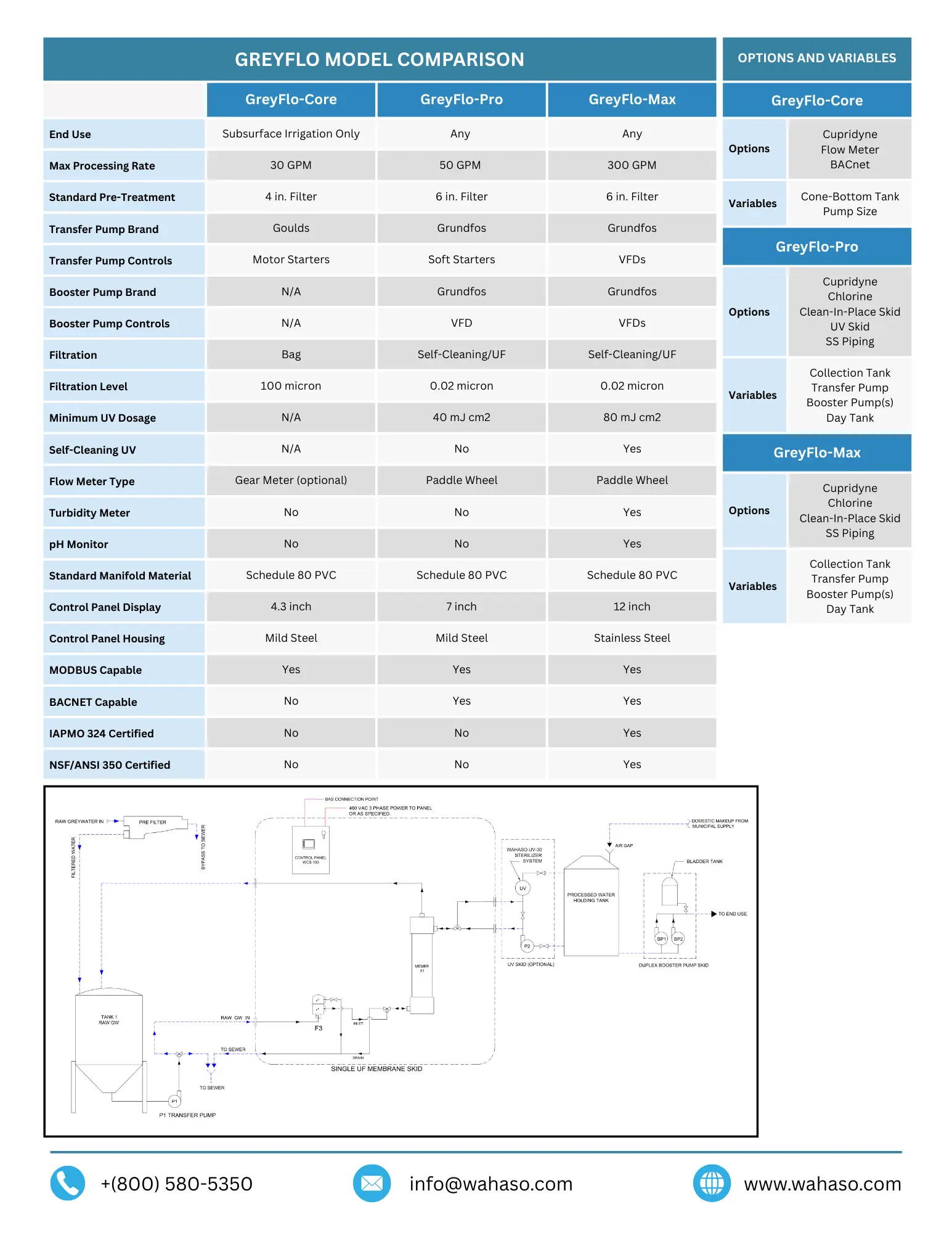

Explore Wahaso’s Packaged Greywater Systems

Greywater (also referred to as graywater, grey water, and gray water) is “gently used” water captured from showers, lavatory sinks, laundry, and light commercial processes.

It can often be an excellent source of water, saving thousands or even millions of gallons of water per year.

IAPMO 324 and NSF/ANSI 350 Certified

GW-UF35-50, GW-UF70-100, GW-UF140-150 and GW-UF210-210 are certified by IAPMO R&T against NSF/ANSI 350 and IAPMO IGC 324.

System Benefits

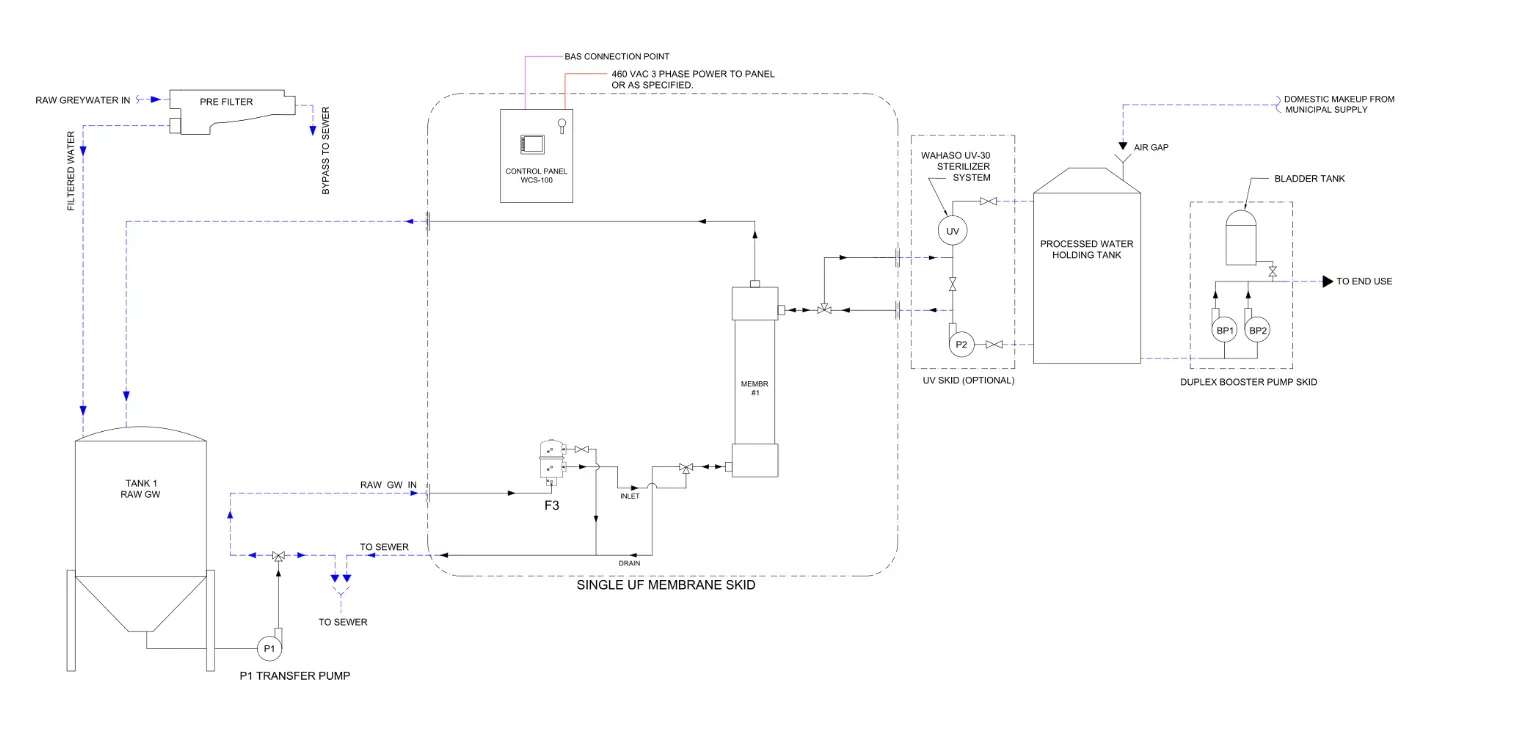

- Fully Automatic Processing. Raw grey water is treated as it is generated to minimize the growth of harmful pathogens.

- Low Maintenance. The system has been designed to run reliably for long intervals, with minimal maintenance required.

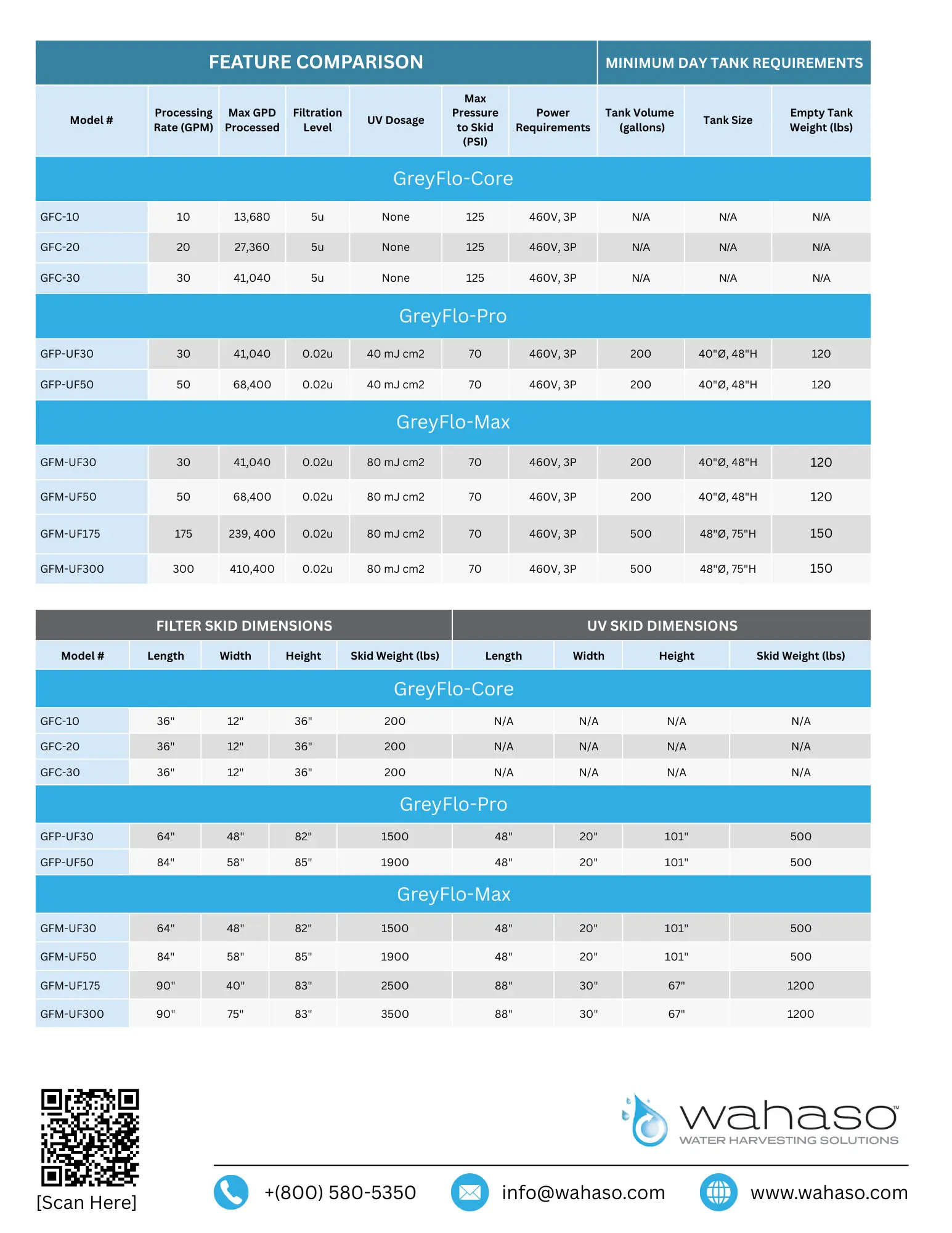

- Scalable. The Wahaso greywater system can be scaled to treat from 2,000 to 200,000 gallons per day or more.

- Robust Controls. Wahaso’s proprietary control system is custom programmed to monitor and track all system activity.

- Integrated System Design. Wahaso’s greywater processing skids are pre-assembled and integrated into comprehensive system designs that include all pumps, storage, filtration, sanitation, and controls.

Standard Systems

Wahaso’s greywater system is fully scalable and able to process 2,000 – 200,000 gallons per day. Each standardized system includes filtration and sanitation equipment. The customizable equipment includes tanks, pressurization, and controls.

For more information on our greywater harvesting systems, download the information sheets.

Filtration

1 Filtration Stage

2 Filtration Stage

3 Filtration Stage

Sanitation

Chlorination

Ultra Violet Sanitation

Storage

All storage systems have a connection to a municipal source so that toilet flushing and other uses can occur even if there is not an adequate supply source of greywater. An air gap inlet can automatically be turned on to make-up water in the treated tank should a supply problem develop in the greywater harvesting system. In typical applications of a greywater system for toilet flushing, there is more than enough supply of greywater from showers and baths to meet flushing requirements.

Wahaso tank systems can be pre-mounted on skids for ease of installation with all internal piping manifolds and sensors mounted and pre-tested at our fabrication center. All of our polyethylene tanks are rated for potable water even though we are not using this water for drinking purposes.

Application of Greywater

We work closely with building engineers to properly size the pumps so that adequate pressure (PSI) and volume (GPM) is available at the farthest – and highest altitude – end point in the system.

Greywater System Monitoring And Control

In addition to monitoring the system mechanicals, the control system can track the amount of water in each tank and track and display the monthly amount of water harvested. An interface allows remote monitoring via a web page for maintenance or educational purposes. Wahaso can use the remote access to help a building maintenance staff diagnose potential system problems.

Ongoing Maintenance

Wahaso Grey Water Systems FAQ’s

To learn how greywater harvesting might be used in your building project, please contact us.

1. What type of water is considered greywater?

2. What is the difference between rainwater harvesting and greywater harvesting?

3. How do you harvest greywater?

4. Is greywater good for the environment?

5. Are greywater systems worth it?

6. Can you filter greywater for drinking?

7. Can you store greywater?

8. Which plants can I water with greywater?

9. Can I use greywater if I have a water softener?

10. What is the difference between stormwater harvesting and greywater harvesting?

Since 2004

Wahaso Mission

Our mission at Wahaso is to help municipalities and commercial property owners reduce the impact of their buildings on the environment through innovative and sustainable water practices.