Rainwater StormFlo Series — By Wahaso

Rainwater Harvesting Systems

Summary

Wahaso commercial rainwater collection system is designed to meet rigorous commercial building and regulatory requirements. Learn more

Key Takeaways

- Smart, Scalable Systems Backed by 20+ Years of Expertise

- Cut utility costs by reusing rainwater for non-potable demand.

- For over two decades, Wahaso has delivered rainwater harvesting systems that balance performance, ease of install, and ROI.

- From early design through final commissioning, we support architects, developers, contractors and engineers with solutions that integrate seamlessly into commercial projects.

- We make sustainability flow naturally into your plans—turning wasted water into lasting value, one system at a time.

Wahaso — StormFlo Series

Packaged Rainwater Systems

The practice of harvesting rainwater dates back centuries and is still the most common type of water harvesting system.

Wahaso specializes in designing and building rainwater harvesting systems for large-scale applications.

Product Features

→ Proven Payback + ROI

Cut utility costs by reusing rainwater for non-potable demand.

→ Trusted Nationwide

Installed in thousands of commercial projects across the U.S.

→ BAS Integration Ready

Compatible with BAS for smart control and performance tracking.

→ Low-Maintenance Design

Automatic filtration and durable components reduce upkeep.

→ Pre-Wired + Pre-Plumbed

Shipped ready to install with minimal onsite labor required.

→ Certified for Compliance

Designed to meet plumbing and filtration code requirements.

Smart, Scalable Systems Backed by 20+ Years of Expertise

For over two decades, Wahaso has delivered rainwater harvesting systems that balance performance, ease of install, and ROI. From early design through final commissioning, we support architects, developers, contractors and engineers with solutions that integrate seamlessly into commercial projects. We make sustainability flow naturally into your plans—turning wasted water into lasting value, one system at a time.

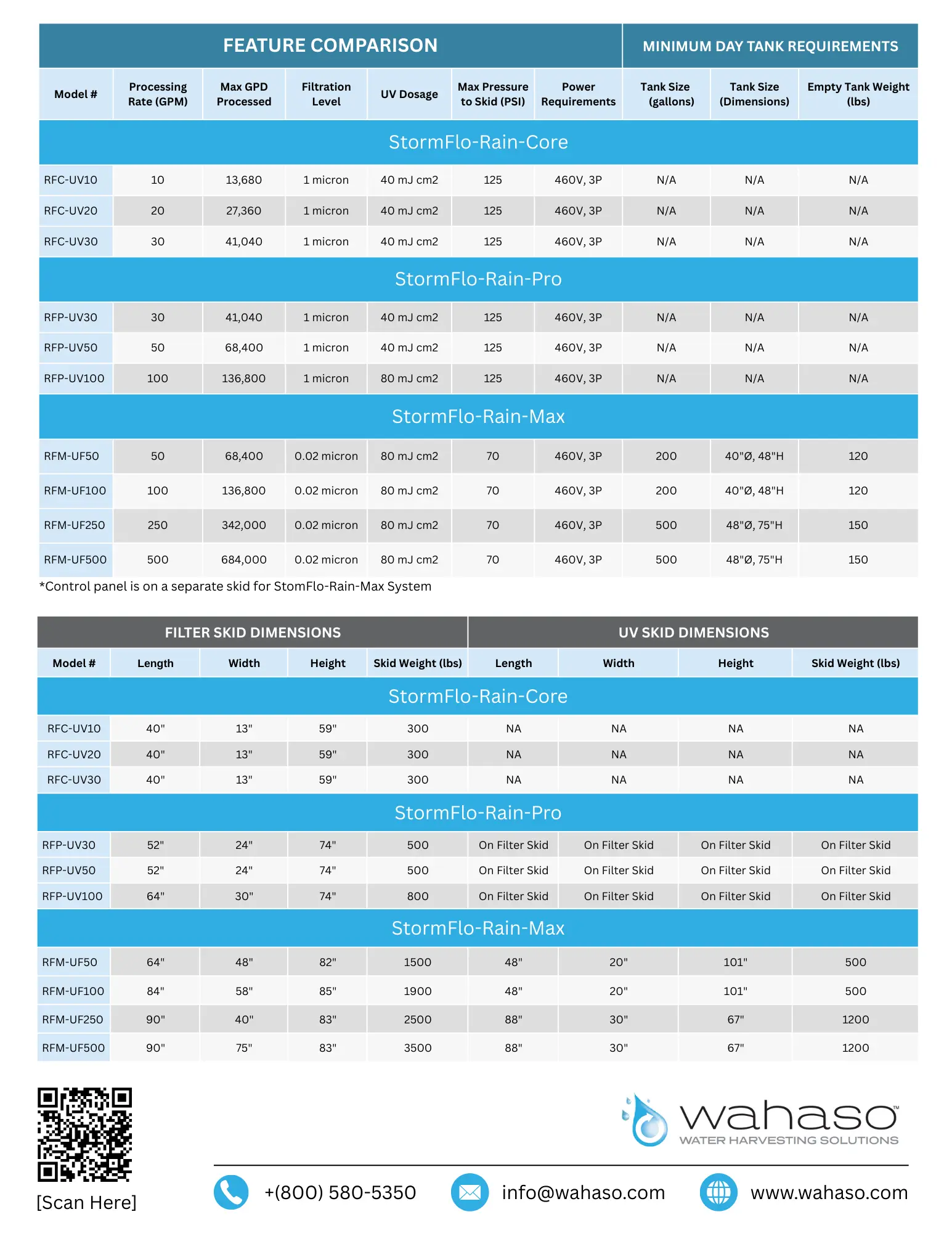

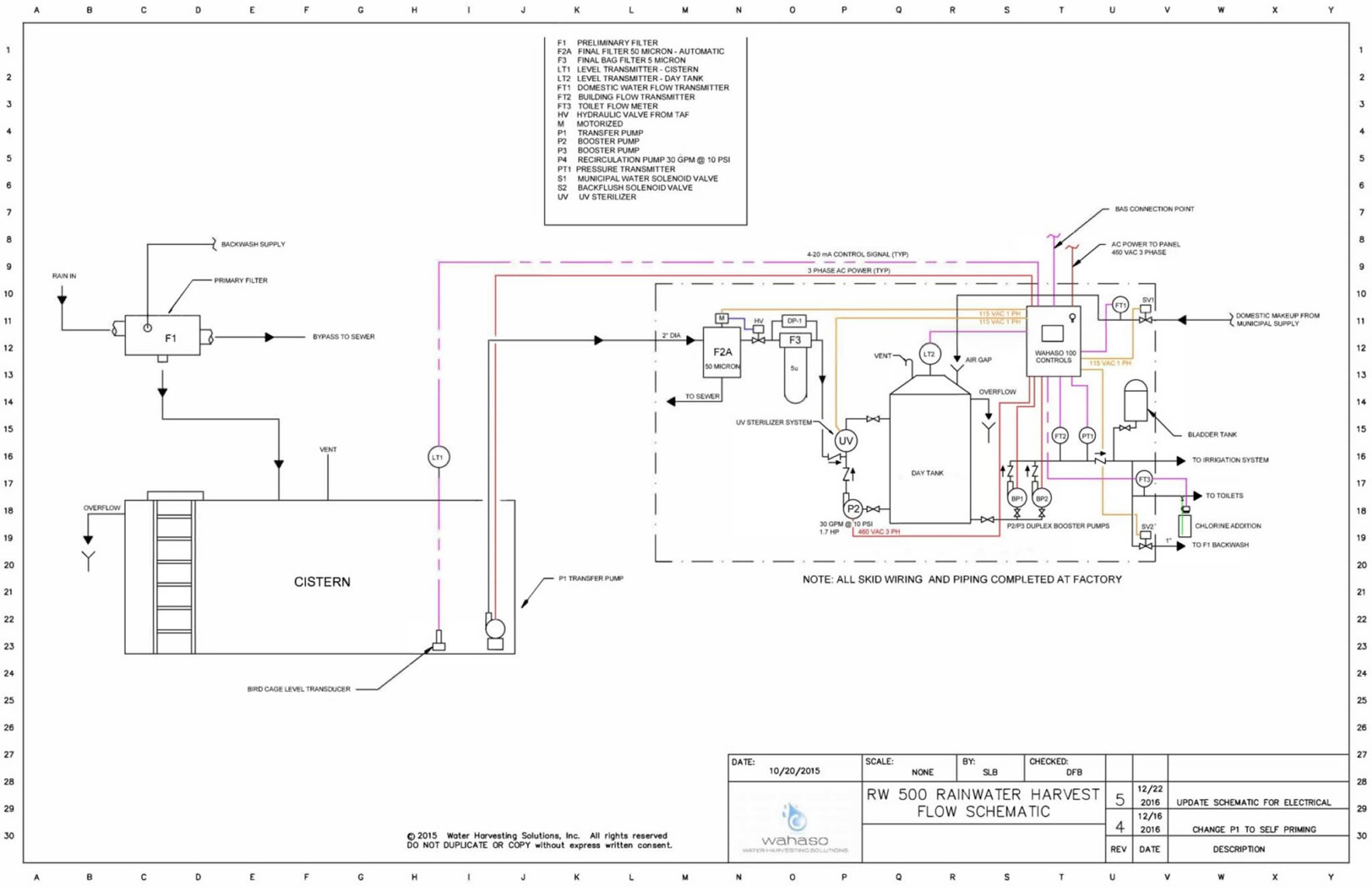

Water Harvesting System Design

Wahaso commercial rainwater collection system is designed to meet rigorous commercial building and regulatory requirements. The first step in any Commercial Rainwater Harvesting Systems is pre-filtration upstream of the cistern. This helps to keep the cistern clean and reduce the load on downstream processing equipment. Wahaso rainwater harvesting for commercial buildings uses a variety of pre-filters including hydraulic jump cascade filters, NSBB units, vortex filters, downspout filters and more.

Harvesting Rainwater

Rooftop Rainwater Harvesting

System Benefits

- The Right Size for the Job. Wahaso’s proprietary pre-design analysis helps to determine the proper size for any rainwater system. A system that is too large is not cost-effective, but under sizing a system can lead to lost potential.

- Low Maintenance. The Wahaso system has been designed for minimal maintenance with few consumables.

- Integrated System Design. Wahaso’s greywater processing skids are pre-assembled and integrated into comprehensive system designs that include all pumps, storage, filtration, sanitation and controls.

- Robust Controls. Wahaso’s proprietary control system is custom programmed to monitor and track all system activity.

Standard Systems

Filtration

First Flush or Pre-Filtration

Organic Filtration

Additional Filtration

Sanitation

Ultra Violet (UV) Sanitation

Chlorination

Harvested Water Storage

Applying Harvested Water

Water Harvesting Monitors And Controls

Wahaso Rainwater Harvesting System FAQ’s

To learn how a rainwater harvesting system might be incorporated into your building plans, please contact us.

1. What are the four main components of a rainwater harvesting system?

The four key components of a rainwater harvesting system are:

- Storage/cistern – This may be above ground, below ground, concrete vault, modular, corrugated, HDPE or fiberglass

- Filtration – This includes pre-filtration prior to water going in the cistern and the type of filtration depends on the type of water and where the system is located

- Sanitation – This can be either UV light, chlorine, ozone or cupridyne

- Controls – Measures tank levels, flow rates, water savings and pump and system statuses.

2. What are the types of rainwater harvesting systems?

3. Are rainwater harvesting systems worth it?

4. How long can rainwater be stored in tanks?

5. What are the limitations of rainwater harvesting?

6. How do you keep rainwater from stagnating?

You can take several precautions to prevent your harvested rainwater from stagnating, including:

- Use the water as often as possible

- Block sunlight from the storage container to prevent bacteria and algae growth

- Cover the container with a tight-fitting lid to keep leaves, twigs, and other organic matter away

- Cycle the water past a UV bulb or chlorine injector

7. What happens when the rainwater tank is empty?

8. How to maintain a rainwater harvesting system?

You can take several measures to maintain a rainwater harvesting system, such as:

Residential systems

- Keep the gutters clean and free of leaves and other debris that may cause water discoloration

- Place cisterns in a shady area to prevent algae growth

- Paint PVC pipes to protect freezing and UV effects

Commercial systems

- Each system will have a maintenance manual to be followed

- Change chlorine and UV bulbs as needed

- Service pumps and other moving components

- Check control system for alerts

9. How much does a rainwater harvesting system cost for commercial buildings?

10. What are the health risks of the rainwater harvesting system?

Tags: Best Rated Rainwater Harvesting Systems, Rainwater Harvesting Systems For Commercial Buildings, How To Select A Rainwater Harvesting System

Since 2004

Wahaso Mission

Our mission at Wahaso is to help municipalities and commercial property owners reduce the impact of their buildings on the environment through innovative and sustainable water practices.