Legionella Control in Cooling Towers: Manage Risk and Push Higher Cycles of Concentration

Cooling towers sit at the intersection of building health, energy performance, and water efficiency.

They also represent one of the most common environmental sources of Legionella risk. Legionnaires’ disease outbreaks are frequently traced back to poorly maintained towers where warm, stagnant water, nutrients, and biofilms allow bacteria to thrive. The good news is that facilities with a solid water management program and effective treatment practices can significantly reduce the risks. When combined with modern side-stream treatment technologies, many operators also find they can use far less water by running at higher cycles of concentration (CoC).

Source: By The Associated Press – August 29, 2025, 8:29 AM

Breaking News! Death toll from Legionnaires’ disease outbreak in New York City rises to 7

New York City health officials have discovered a seventh death linked to a Legionnaires’ disease outbreak in Central Harlem, where more than 100 people have been diagnosed with the ailment.NEW YORK — New York City health officials have discovered a seventh death linked to a Legionnaires’ disease outbreak in Central Harlem, where more than 100 people have been diagnosed with the ailment.

The latest death was announced Thursday. Officials said they had concluded the death of a person with the disease who died before mid-August is associated with the cluster.

Officials said 114 people have been diagnosed with Legionnaires’ disease as of Thursday, while six people are hospitalized.

The bacteria that causes Legionnaires’ disease had been discovered in 12 cooling towers on 10 buildings, including a city-run hospital and sexual health clinic, health officials said. Remediation efforts have since been completed on all of the cooling towers.

Legionnaires’ disease is a type of pneumonia that is caused by Legionella bacteria, which grow in warm water and spread through building water systems. The city’s outbreak has been linked to cooling towers, which use water and a fan to cool buildings.

Why proactive programs matter (and what regulators expect)

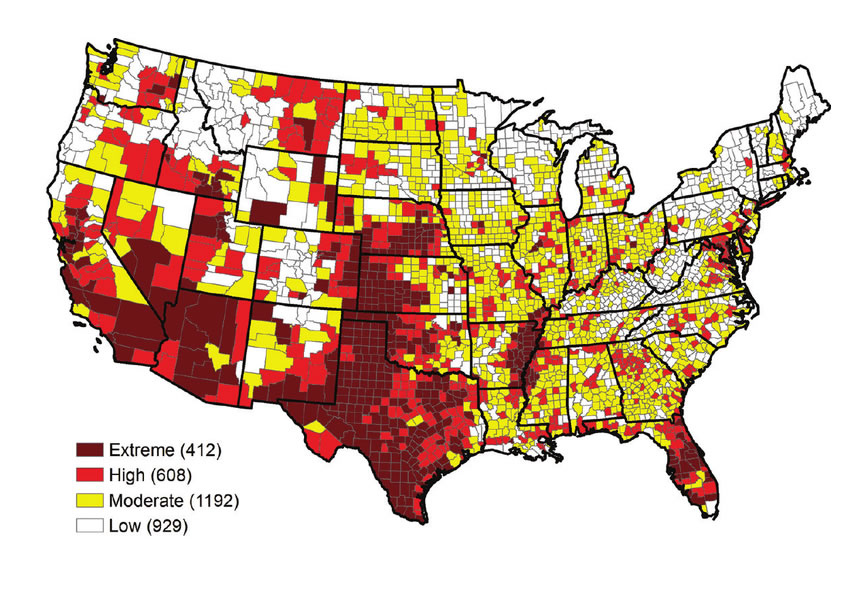

National and local guidance emphasizes prevention. The Centers for Disease Control and Prevention (CDC) has published a comprehensive Water Management Program (WMP) Toolkit that identifies cooling towers as a high-risk system and recommends a tailored plan for each facility. A WMP should define control limits (for disinfectant residuals, temperature, conductivity, etc.), outline maintenance schedules, and require verification through testing. OSHA echoes this in its own technical manual, highlighting design, cleaning, and ongoing maintenance as essential steps in Legionella prevention. Local authorities often go further: New York City’s Health Code Chapter 8 requires quarterly Legionella testing by approved labs, specific maintenance practices, and even mandates emergency testing if conductivity controls (which regulate cycles of concentration) fail.

How detection fits in

Testing is a critical part of verifying that a WMP is effective. According to CDC, routine environmental sampling of cooling tower water should be included in the program, with culture methods used to confirm the presence of live Legionella bacteria. Culture testing is still the gold standard, though results may take 7–10 days. PCR testing provides faster screening but may detect DNA from both live and dead cells. Rapid immunoassays or field tests can offer immediate insights but are not sufficient for compliance. In many programs, culture and PCR are used together—PCR for quick insight, and culture for definitive confirmation. In cities such as New York, tests must be performed by CDC ELITE-certified or state-approved labs.

The problem in towers: biofilm + solids = a friendlier habitat for Legionella

- Legionella does not exist in isolation. It thrives in the complex ecology of cooling towers, especially where biofilms form. Biofilm acts as a protective layer for bacteria, making them harder to kill with disinfectants.

- Suspended solids and organic matter feed this biofilm, while stagnant areas and low disinfectant residuals create pockets where Legionella can multiply.

- Because of this, the most effective programs don’t rely on a single treatment. Instead, they combine chemical, physical, and operational measures to keep systems clean and under control.

Conventional Legionella Management Approaches

Most facilities already employ a mix of conventional tools to control Legionella. These methods are proven but each comes with tradeoffs:

- Chemical Biocides (Chlorine, Bromine, Oxidizers/Non-Oxidizers): The backbone of most cooling tower programs, biocides kill bacteria and disrupt biofilm. Pros: Fast-acting, widely used, proven effectiveness. Cons: Reduced effectiveness in heavy biofilm; requires continuous monitoring and chemical handling. Overuse can add cost and create corrosion or safety risks.

- Thermal Control (Heat-and-Flush): Periodic use of elevated water temperatures or flush cycles to kill bacteria. Pros: Effective in hot-water plumbing systems. Cons: Not practical for cooling towers due to their operating conditions; energy-intensive.

- Copper-Silver Ionization: A secondary disinfection technology that disperses ions toxic to bacteria. Pros: Effective against bacteria within biofilms; provides residual throughout piping. Cons: Requires monitoring and calibration; upfront investment; some states regulate its use.

- Ultraviolet (UV) Disinfection: Sidestream UV chambers neutralize bacteria as water flows past. Pros: Immediate kill, no chemicals. Cons: Works only at the point of exposure; no residual; requires lamp maintenance.

- Sidestream Sand or Media Filtration: Removes suspended solids that harbor bacteria. Pros: Helps reduce biofilm precursors. Cons: Limited in removing fine particulates or bacteria; not a disinfection method.

Most facilities combine these methods into multi-barrier programs. But one challenge remains: as solids accumulate, water becomes harder to disinfect, forcing higher chemical use and increasing operating costs.

Wahaso’s CT Recover: One Tool to Support Cleaner Water

To address that challenge, Wahaso developed CT Recover, a side-stream treatment system designed specifically for cooling towers. CT Recover uses modified ultrafiltration (UF) membranes with a nominal pore size of ~0.02 microns. This creates a physical barrier that removes fine suspended solids and bacteria from circulating water. The result is cleaner water—with more stable chemistry and reduced biofilm pressure—so the facility’s broader program can operate more effectively.

The water-efficiency win: push cycles of concentration higher

Beyond microbiological benefits, CT Recover also supports water efficiency. Both EPA WaterSense and the Department of Energy (DOE) encourage maximizing cycles of concentration as one of the most effective ways to reduce water use in cooling towers. Cleaner circulating water makes this easier by stabilizing conductivity, pH, and corrosion/scaling inhibitors. Many facilities find that after installing advanced side-stream treatment, they can run more cycles with fewer chemical upsets—saving significant volumes of make-up water and reducing blowdown.

Closing the loop with compliance

Better side-stream treatment can also reduce regulatory headaches. For example, New York City requires additional Legionella sampling when conductivity controls fail to maintain cycles—a sign of poor chemistry control. By helping maintain cleaner, more stable water, CT Recover can support compliance efforts and reinforce WMP targets.

Putting it all together: A multi-barrier approach

The most effective recipe for managing Legionella in cooling towers includes:

- Water Management Program (WMP) per CDC/industry standards with defined limits and responsibilities.

- Routine hygiene: physical cleaning, seasonal startup/shutdown procedures, and corrective disinfection per CDC/OSHA.

- Chemistry control: maintain disinfectant residuals, pH, and CoC targets with scaling/corrosion inhibitors.

- Side-stream UF (CT Recover): continuously remove fine particulates and bacteria to reduce biofilm pressure and stabilize chemistry.

- Verification: periodic environmental testing by qualified labs, with corrective actions if limits are exceeded.

The takeaway

Legionella control is not solved by a single device or chemical. Every cooling tower requires a comprehensive, facility-wide water management program that integrates monitoring, chemical treatment, maintenance, and testing. Within that broader strategy, Wahaso’s CT Recover system can be an important supporting tool—helping reduce solids and microbial load, stabilizing water chemistry, and enabling higher cycles of concentration. That balance—public health protection, regulatory compliance, and water efficiency—is the foundation of effective Legionella risk management.

Since 2004

Wahaso Mission

Our mission at Wahaso is to help municipalities and commercial property owners reduce the impact of their buildings on the environment through innovative and sustainable water practices.