Stormwater Detention Systems and Reuse Opportunities for Commercial Projects

Detention temporarily stores runoff and then releases it at a controlled rate so post-development peak flows approximate pre-development conditions (mitigating flooding/erosion). It’s different from retention/infiltration, which keep water on site (infiltrating to soil or reusing). Many modern systems can be configured for detention, retention, infiltration, or combinations.

Common detention system types & representative manufacturers

1) Modular precast concrete vaults

- Concept: Large underground chambers assembled from modular precast units. High load capacity under parking/roadways, shallow cover options, long service life, easy access for maintenance.

- Manufacturers & approaches:

-

- StormTrap – SingleTrap (single-layer) and DoubleTrap (dual-layer) precast modules sized to site constraints; can integrate detention, infiltration, and even harvesting/treatment “trains.

-

- Oldcastle Infrastructure (StormCapture®) – modular precast system (typical inside module ~7’×15′); designed for detention/retention/infiltration/harvesting, optimized for installation under traffic areas with minimal cover.

2) Corrugated or reinforced pipe systems

- Concept: Arrays of CMP (corrugated metal pipe) or large-diameter SRPE/HDPE pipe provide the storage volume; manifolds control inflow/outflow.

- Manufacturers & approaches:

-

- Contech – broad portfolio including CMP detention/infiltration (12″–144″ diameters) and DuroMaxx® SRPE for large volumes and long runs; can tune geometry to site footprint.

3) Plastic arch chambers

- Concept: Rows of open-bottom HDPE arches on stone beds; stone voids add storage. Efficient for shallow covers; common for both detention and infiltration.

- Manufacturers & approaches:

-

- ADS StormTech® – widely used arch chamber families with tools for design and installation support.

-

- Contech ChamberMaxx® – arch chambers for detention/infiltration with design guides and standard details.

4) Modular plastic crate systems

- Concept: Stackable geocellular “crates” create large void ratios in tight footprints; typically wrapped to function as detention or infiltration.

- Manufacturers & approaches:

-

- Examples include R-Tank/geo-cell systems (various suppliers); selected for constrained urban sites; often marketed as “underground ponds.”

Most sites pair detention with pretreatment (sediment/debris control) and flow-control structures (orifices, weirs, valves) to meet municipal stormwater permits. Some systems, like StormTrap, explicitly market integrated treatment or placement within a broader treatment train.

From detention to reuse (non-potable applications)

When detention storage is coupled with appropriate treatment, that water can become a reliable non-potable supply for:

- Cooling-tower make-up

- Irrigation

- Toilet/urinal flushing

- Process water, washdown, decorative water features, etc.

A typical reuse train for stormwater includes:

- Screening/pretreatment (trash, grit, gross solids)

- Filtration/UF (suspended solids, turbidity)

- Disinfection (UV and/or chlorine)

- Polishing/storage with controls, monitoring, and make-safe bypasses

Many detention assets (vaults, chambers, ponds) can double as the primary capture reservoir, with a pumped draw-off to a treatment skid that feeds end uses. Several vault products explicitly support harvesting configurations.

Detention vs. Retention: Key Differences

Although the terms are often used interchangeably, detention and retention describe very different stormwater management strategies. Detention systems temporarily store runoff and then release it slowly to downstream sewers or waterways, primarily to control peak flows and reduce flooding risk. By contrast, retention systems (sometimes called infiltration or retention basins) are designed to hold water permanently on site—either allowing it to infiltrate into the ground, evaporate, or be harvested for reuse. In practice, detention is usually a regulatory requirement for flood control, while retention provides additional water-quality and sustainability benefits by keeping water out of municipal systems altogether.

How Wahaso supports design—and leverages detention assets

Wahaso works upstream with owners, architects, and MEP/civil teams to:

- Identify viable sources (stormwater, rainwater, condensate, greywater) and end uses.

- Integrate with detention: We can draw from existing or planned detention (including detention ponds) as the capture source, minimizing new footprint.

- Engineer the treatment train to local code/permit requirements and desired water-quality targets (cooling towers, irrigation, toilets).

- Provide controls/monitoring for reliability, compliance data, and O&M simplicity.

Reference projects using detention/capture for reuse

- Orange Memorial Park Regional Stormwater Capture Project (South San Francisco, CA): Regional project that diverts flows from Colma Creek, pretreats, stores in an underground cistern, and applies advanced treatment for non-potable reuse—illustrating the detention-to-reuse pathway at scale.

- Bolivar (Simón Bolívar) Park, Lakewood, CA: Stormwater is diverted from a flood-control channel, pre-treated, and conveyed into a StormTrap system; Wahaso’s published case study notes the system manages tens of millions of gallons annually, producing water suitable for spray irrigation and offsetting >4 million gallons/year of municipal supply.

Selecting the right detention platform for reuse

- Footprint & cover: Precast vaults excel under traffic with shallow cover; arches/crates shine where excavation depth is limited.

- Volume & geometry: CMP/SRPE pipes scale easily for long, linear footprints; modular precast optimizes cubic storage under parking fields.

- Maintenance access: Precast vaults typically offer the best internal access; arches/crates demand upstream pretreatment and clear maintenance plans.

- Regulatory objectives: If detention is the permit driver, weirs/orifices govern outflow; for reuse, add the treatment skid, QA monitoring, and potable make-up safeguards (code-driven). Products like StormTrap/StormCapture explicitly support detention and harvesting configurations.

Bottom line

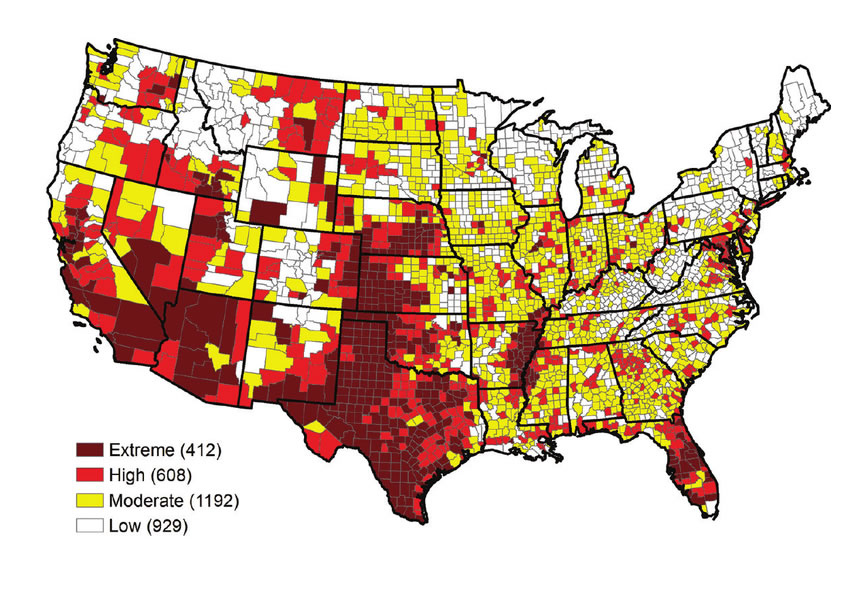

Detention infrastructure isn’t just a compliance cost center. With the right platform and a Wahaso treatment/control package, it becomes a distributed water supply for cooling towers, irrigation, toilet flushing, and more—often yielding operational savings, LEED contributions, and resilience benefits while still meeting stormwater peak-flow requirements.

Start with a Water Audit — We’ll Help You from There

If you haven’t conducted a recent water audit at your facility, now is the time. Whether your goal is cost savings, LEED certification, or municipal compliance, Wahaso can help identify which water harvesting strategies make the most sense—and deliver the most value.

Since 2004

Wahaso Mission

Our mission at Wahaso is to help municipalities and commercial property owners reduce the impact of their buildings on the environment through innovative and sustainable water practices.